|

Xinxiang Doing Renewable Energy Equipment Company

|

2013 Hot Sell!!! Chinese High Tech Crude Oil Recycling Equipment

| Price: | 40000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.CE, ISO, SGS

2.Domestic pioneer of this technology .

3.Good after sale service

4. Fast delivery time

5. The reasonable price

The whole pyrolysis system named used tire recycling machine is composed by 13 parts, which are reactor, transmission device, catalytic chamber, cooling tube, heavy tank, oil-water separator, condenser, light oil tank, safety device, vacuum system, dedusting system, draft fan, chimney.

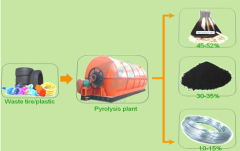

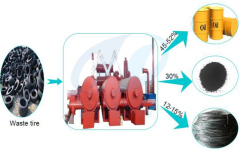

(1)What can we get from the tire pyrolysis machine?

fuel oil  steel wires

steel wires

carbon black

carbon black

(2) The usage of final productions

Fuel oil -- power plant factory

glass factory

cement factory

ceramic factory

aluminum factory

boiler factory

central heating factory

painting factory

Carbon black -- electric cable jacketing

conveyor ban

hose and doormat

blacknylon bag

rubber additive

automatic spare parts

heat isolation

black colorant in rubber materials

plastic pipes

industies rubberproducts

fire fighting

Steel wires -- be re-sale to steel factory

(3)Process time about Doing tires recycling machine/equipment/plant

Style | Feeding Time (hours) | Processing Time (hours) | Cooling Time (hours) | Slag Outlet Time (hours) |

DY-2200-6000 | 2 | 8 | 2 | 2 |

DY-2200-6600 | 2 | 10 | 2-3 | 2-3 |

DY-2600-6600 | 2 | 13 | 3 | 2 |

(4) Technical parameter

Technical parameter of DOING Pyrolysis Equipment | ||||

Items | Contents | |||

1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

2 | Raw material | tires/Plastic | tires/Plastic | tires/Plastic |

3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

5 | Oil yield | 2.7ton | 3.6 ton | 4.5 ton |

6 | Operating pressure | Normal | Normal | Normal |

7 | Material of Reactor | Q345R | Q345R | Q345R |

8 | Thickness of Reactor | 14mm | 14mm | 16mm |

9 | Rotate speed of Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

10 | Total power | 12KW | 12KW | 23.5KW |

11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

12 | Cooling area of condenser | 40sqm | 40sqm | 65sqm |

14 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

16 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

17 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

18 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

19 | Delivery time | 20days | 20days | 20days |

20 | Weight | 30T | 35T | 45T |

(5) Main features:

Safety:

1. Professional sealing technology for cover, oil outlet

2. Heavy oil is separated which can avoid the problems of jam in later condensing

3. Vacuum system will prevent exhaust gas from going back to reactor and causing accident

4. Alarm, safety valves, thermometer, pressure gauge and safety valve

5. It is dangerous to burning exhaust gas (C1 to C4). In our process, it is transferred first through the safety device and a safety burning air muzzle

Environment friendly:

1. Well water dedusting system with high pressure nozzle and environmental damper inside can avoid black smoke

2. The exhaust gas will be directly recycled for heating reactor, no gas pollution

3. Every junction of the reactor is in good sealing situation with professional sealing material

Long service life:

1. Material: Q245R special steel plate, thickness 14mm

2. The service life of the reactor will be 8 years

Energy saving:

1. Well sealing for heatingsystem, no gas leak and saving fuel

2. The exhaust gas will be recycled for reactor heating

(6) Our factory and customers

We have mature technology and professional sales team. Our factory covers an area of 20000 square meters.We have professional engineers and skillful technicia-ns with rice installation and commissioning experience. Monthly production capacity exceeds 20 sets. And we have exported more than 50 sets of equipments to many countries and areas in 2011, such as Turkey, Albania, Macedonia, Iran, Ecuador, Poland, India, Malaysia, Bangladesh and so on.