|

Xinxiang Doing Renewable Energy Equipment Company

|

Waste tyre to oil recycling process pyrolysis plant

| Price: | 480000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

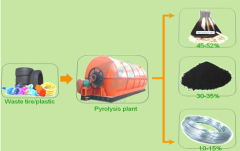

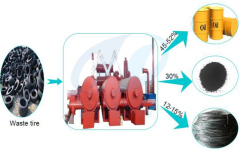

Waste tyre to oil recycling process pyrolysis plant the obtain thing as follows: 45%-55% fuel oil, 10%-15% steel wire, 30%-35% carbon black and 8%-10%

Waste tyre to oil recycling process pyrolysis plant

Waste tyre to oil recycling process pyrolysis plant the obtain thing as follows: 45%-55% fuel oil, 10%-15% steel wire, 30%-35% carbon black and 8%-10% flammable gas. You can get diesel from fuel oil by distillation plant.

You can get a very high profit by disposing these wastes, and also it's helpful for improving the local environment, avoid garbage pollution.

Waste tyre to oil recycling process pyrolysis plant advantages:

1. One week installation:no need to build foundation thus shorten

the construction period, 4th and 5th machine installation period is one month, 6th machine install only need one week. Also easy to move.

2. Service life: Special design inside the reactor to avoid direct heating, so machine service life prolong to 3-5 times and the heating energy can realize 100% utilization.

3. De-dusting system: "Four in one" de-dusting system can reach

European standard, 100% environmental friendly.also no need building the water pool, saving cement, brick cost, saving time.

4. Cooling system:

A. 36 meters cooling condenser pipe, inner each pipe have 4 small pipe, cooling performance is very good.

B. "Four in one" condensing systems.

Waste tyre to oil recycling process pyrolysis plant final product application

Fuel oil

Fuel oil application

As the fuel material used in Cement factory, glass factory, ceramic factory, electric power factory, steel making factory, boiler factory, etc.

2. Final diesel come out from our distillation plant and deodorant

& decolorant can be used in diesel generator.

3. Used in diesel powered cars, such as vans, truck, tractor, etc.

4. Use as heating oil, industrial and home.

Carbon black :

1. Make it to briquette for fuel.

2. Used in rubber and painting factory after carbon black grinding to 200-4000 mesh.

Steel wire:Sell to iron and steel factory

(you can take out steel wire from tyre before pyrolysis)

Waste gas:

1. Recycled into furnace heating reactor instead of coal/wood/oil/natural gas.

2. Storage the exceed gas to restart the next batch.

Skype: bonniezhao2

www(dot)wastetireoil(dot)com